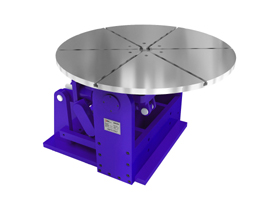

Turntables

SprayWerx SXT series turntables come in various sizes for specific customers requirements:

|

Model Number |

Load |

Rotational Speed (RPM) |

Tilting |

Face Plate Diameter |

Remarks |

| SXT-300 |

300 kg (660 lb) |

0-300 |

No |

600 -1,200 mm (24 – 47 in) |

|

| SXT-300R |

300 kg (660 lb) |

0-300 |

Yes |

600 -1,200 mm (24 – 47 in) |

90kg load at 60 degree tilt |

| SXT-500 |

500 kg (1100 lb) |

0-300 |

No |

600 -1,200 mm (24 – 47 in) |

|

| SXT-500R |

500 kg (1100 lb) |

0-300 |

Yes |

600 -1,200 mm (24 – 47 in) |

150kg load at 90 degree tilt |

| SXT-1000 |

1,000 kg (2200 lb) |

0-90 |

No |

1,500 mm (59 in) |

|

| SXT-10T |

10,000 kg (22,000 lb) |

0-30 |

No |

2,500 (98 in) |

Turntable features, benefits and options:

|

Carousel turntables are ideally suited to spray a large quantity of small parts. The carousel turntable allows for continuous processing with high process efficiency and less material waste.In the carousel mode, satellites spindles are used to coat small identical parts. The large faceplate is indexed for continuous operation to the next spindle and the process is repeated. This efficient movement allows for improved efficiency resulting in less powder waste and improved product throughput.

Custom designs for unique requirements are available. |