Delta 3 Anode Plasma

The GTV Delta gun is a rugged industrial tool that produces high quality surface engineered coatings. Delta Plasma torch uses 3 anodes with one cathode. This configuration allows for systems in production in industries ranging from:

- IGT

- Printing Rolls

- Paper Rolls

- Steel Mill

- PVD Targets

- Large area spraying of ceramics

- Powder Spherodizing

- Powder Processing

Delta Gun and Coating Features

- 3 Anode, 1Cathode

- Cascading plasma for long arc, high voltage/low current operation

- 1 power supply

- Argon/ Hydrogen plasma gas mixtures (standard)

- Easy to change electrodes

- Fixed anode arc root locations, not depending on plasma gas flow rate and composition or current level

- 3 powder injectors focus into “hot spots” of plasma adjacent to the anode arc root

- Stable Arcs, voltage ± 3 V

- Low wear cathode

- Variable nozzle diameters for parameter optimization

Key Applications

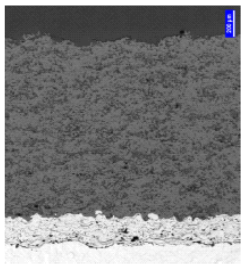

- Thick TBC coatings (2 mm with > 20% porosity)

- Anilox Cr2O3 coatings

- Corona Treater Roll coatings (Al2O3, Al2O3/Cr2O3)

- Y2O3 coatings for semi-conductor tools

- MCrAlY/Al2O3 for steel mill hearth rolls

- Printing machine rolls (Al2O3/TiO2)

- Silicon, ZnO/Al2O3 for solar applications

- Si, Si/Al, TiO2 for PVD targets (Currently under licensed to Heraeus company)

- NiCr bond coats